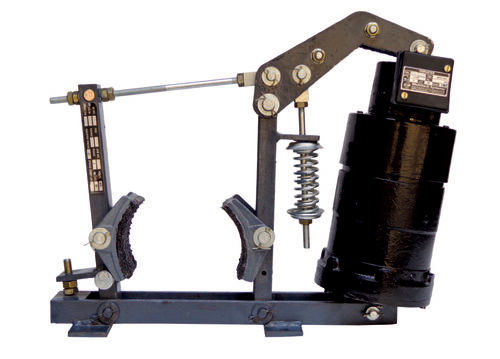

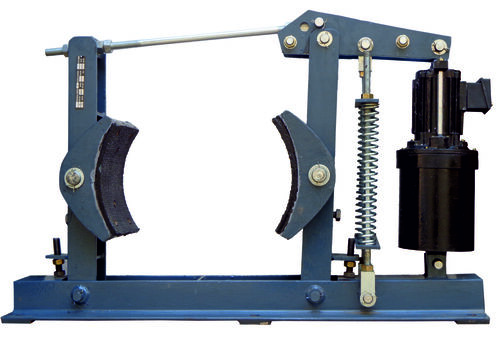

Thruster Brakes 150-18

Price 11300 INR/ Number

MOQ : 1 Number

Thruster Brakes 150-18 Specification

- Usage

- Eot Crane

- Material

- Metal

- Size

- Standard

- Product Type

- Thruster Brakes 150-18

- Weight

- 29 Kilograms (kg)

- Color

- Black

- Application

- Eot Crane

Thruster Brakes 150-18 Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Thruster Brakes 150-18

| Material | SS, Alloy |

| Usage/Application | Eot Crane |

| Drum Diameter | 150 |

| Finishing | Galvanised |

| Braking Torque | 7.5 kg-m |

| Voltage | 415V |

| Oil Capacity | transformer oil 2 litrs |

| Thrustor Stroke | 51mm |

| Weight | 18 kg |

| Brand | Multitech Systems |

| Country of Origin | Made in India |

- Model=MDT 150-18

- Drum Dia=150mm

- Brake shoe=asbetos free/BA

- Braking torque=7.5kg-m

- Thrust=18kg

- Stroke=51mm

- Oil+capacity=transformer oil 2 litres

- Weight=11kg

Precision Engineering for EOT Cranes

Thruster Brakes 150-18 are meticulously crafted to meet the stringent demands of EOT crane operations. Their metal construction ensures strength, consistent performance, and resilience under heavy loads, providing safety and reliability in industrial environments.

Trusted Supplier from India

As a leading exporter, manufacturer, and supplier in India, we are dedicated to supplying top-quality thruster brakes both domestically and internationally. Our comprehensive support and after-sales service assure lasting customer satisfaction for EOT crane users.

FAQs of Thruster Brakes 150-18:

Q: How are Thruster Brakes 150-18 installed on EOT cranes?

A: These brakes are designed for standard mounting on EOT cranes, allowing for straightforward integration into existing crane assemblies by following the manufacturers recommended installation guidelines.Q: What is the primary function of the Thruster Brakes 150-18 in crane operations?

A: Their main function is to enhance safety by providing controlled braking power, enabling secure movement and reliable stopping of the crane during lifting operations.Q: When should Thruster Brakes 150-18 be maintained?

A: Regular maintenance, such as inspection and adjustment, should be performed according to the crane manufacturers schedule or whenever a decrease in braking efficiency is observed to ensure optimal performance.Q: Where can I source Thruster Brakes 150-18 in India?

A: You can obtain these brakes directly from reputable exporters, manufacturers, and suppliers across India, including our company, which specializes in industrial crane components.Q: What is the process for exporting Thruster Brakes 150-18?

A: The export process involves placing an order with the manufacturer or supplier, quality checks, packaging, and arranging logistics to deliver the brakes safely to your preferred international location.Q: Why are metal thruster brakes beneficial for EOT crane usage?

A: The metal construction provides high durability, withstands heavy-duty applications, and ensures prolonged operational life, making them ideal for demanding crane environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thruster Brake Category

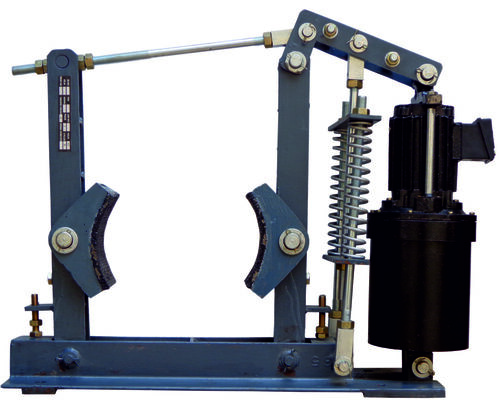

Thruster Brakes 200-34

Price 15600 INR / Number

Minimum Order Quantity : 1 Number

Material : Metal

Product Type : Thruster Brakes 20034

Color : Grey

Usage : Industrial

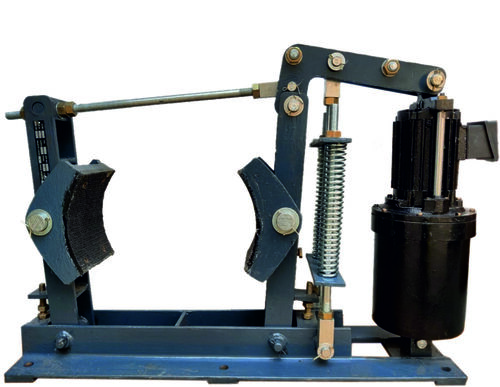

Thruster Brakes 250-34

Price 16600 INR / Number

Minimum Order Quantity : 1 Number

Material : Metal

Product Type : Thruster Brakes 25034

Color : Black

Usage : Industrial

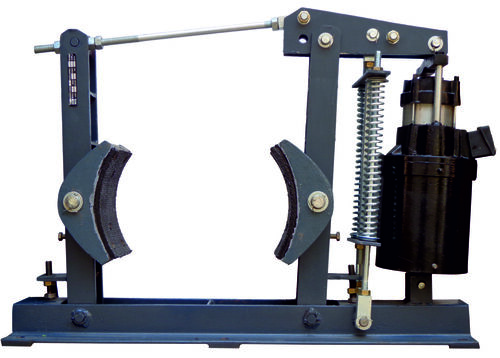

Thruster Brakes 400-68

Price 30420 INR / Number

Minimum Order Quantity : 1 Number

Material : Metal

Product Type : Thruster Brakes 40068

Color : Grey

Usage : Industrial

Thruster Brake 400-34

Price 24500 INR / Number

Minimum Order Quantity : 1 Number

Material : Metal

Product Type : Thruster Brake 40034

Color : Black

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free